CE Engineering Solutions AB (Volvo CE subsidiary) and Norrhydro Plc will bring NorrDigi® MCC technology to the construction machinery market during the spring 2025. NorrDigi MCC is based on the Multi-Chamber Cylinder technology developed through a joint project by Volvo Construction Equipment and Norrhydro during many years. The field tests carried out in Tampere, Finland in the winter of 2023/24, have shown great results, cutting fuel bills and CO2 emissions in construction applications by -50%. When adopted at scale, the system will significantly help stakeholders and industry to meet sustainability ambitions, while at the same time improving machine productivity.

CE Engineering Solutions (CEES) from Sweden and Finland’s Norrhydro, will bring a new technology to the market that is set to revolutionize machine's hydraulic performance. Climate benefits have shown to be radical, with machine fuel efficiency significantly increased and CO2 emissions being cut by up to -50%. The achieved results are far beyond anything else available for the heavy construction equipment market.

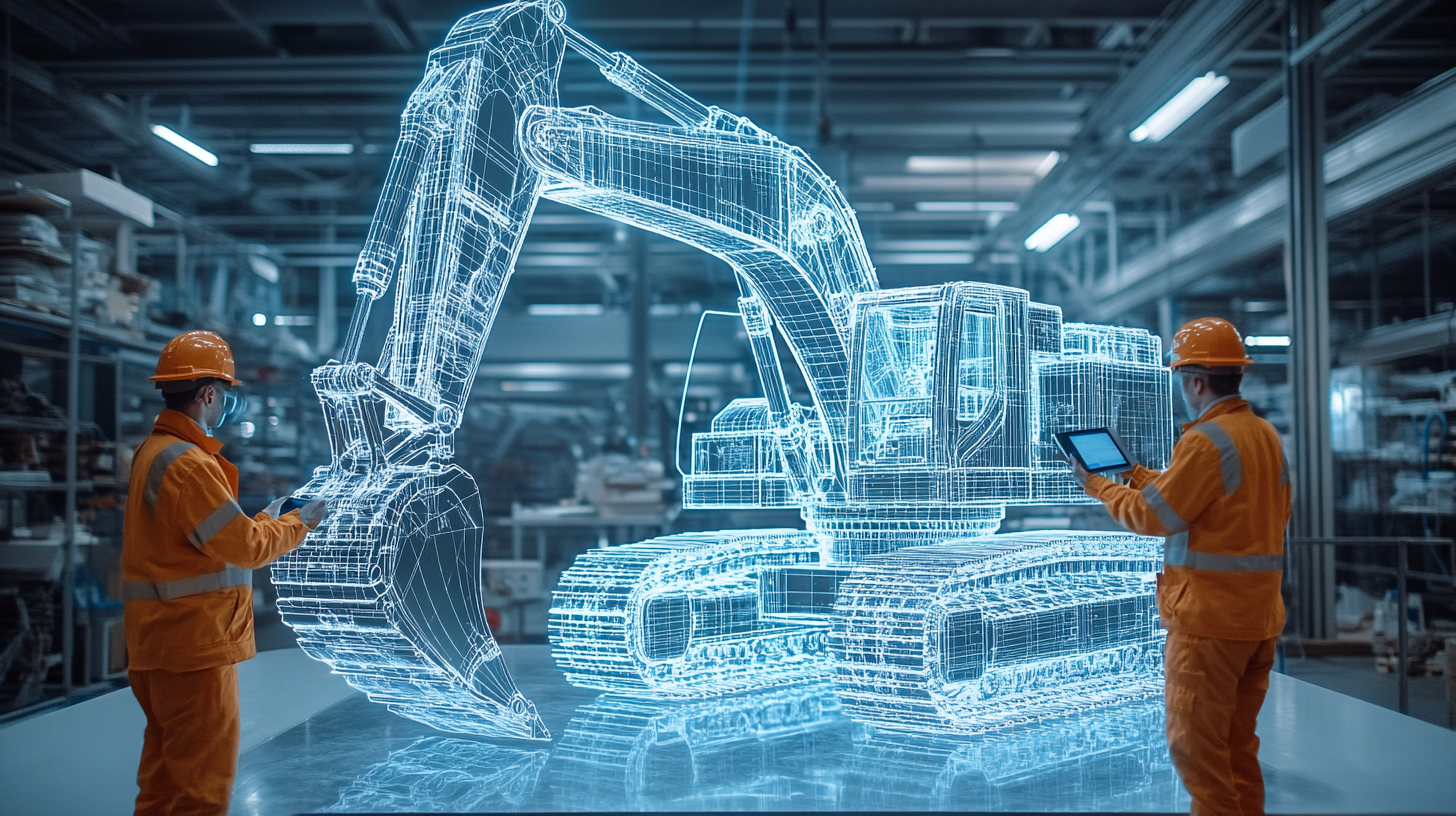

The NorrDigi® MCC, system patented by Norrhydro, uses a multi-chamber digital hydraulic actuator that improves system efficiency and thus enables discarding or downsizing much of a machine’s hydraulic system. NorrDigi MCC removes the need for a main control valve – the heart of a traditional hydraulic system – along with excessive pump capacity, piping and hoses. In addition, the system uses less energy and offers the possibility of downsizing the engine.

The system validation was done during 2023-24 at works sites in Tampere, Finland and assisted by Tampereen Infra Ltd. The test results demonstrated significant fuel efficiency improvement of -50% compared to conventional machine of the same size and excellent machine maneuverability. Operators using the test machine were praising both fast and smooth commands combined with the extremely low fuel consumption. Utilizing NorrDigi MCC technology helps end-users like Tampereen Infra Ltd to reach their goals of making the cities carbon neutral by 2030.

Smart cylinders

Unlike traditional cylinders with two chambers – one pushing, and one pulling – the NorrDigi digital hydraulic actuator uses four chambers. “We use advanced electronic controls and only a fraction of the energy for the same machine maneuver compared to a traditional system,” says Carl Mattson, Digital Business Director of Norrhydro.

Read more about fuel fuel-saving NorrDigi MCC -system

“This is a perfect project for CEES as we can bring new sustainable technical innovation developed by Volvo Group to the market through selective market introductions before scaling up production,” says Henrik Loserius, Managing Director of CEES. The NorrDigi MCC technology can also be used in combination with other sustainable power solutions.

Moving from field test to market launch

With a Volvo EC300 30-ton excavator as a test bed, the NorrDigi MCC technology has passed its field test and is preparing for launch in selective markets. “The ability to launch NorrDigi MCC in partnership with CE Engineering Solutions AB offers the advantage of speed to market” says Yrjö Trög, CEO of Norrhydro Plc. “We have invested substantially in a world-class production facility to support the launch, and now it is time for action“, he concludes. CE Engineering Ab and Norrhydro Plc will bring the first commercially available excavators (of model EC300 Volvo excavator) to the market in 2025.

SUBMIT YOUR COMMENT